Securitron SAM Shear Aligning Magnalock Manuel utilisateur

PDF

Dokument

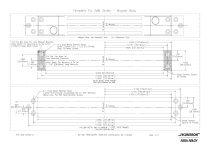

Template For SAM Series — Magnet Body

e out [his Area For, Lock To Be 1/18" - 5.425 [137.80mm] на

ote. De or Mounting Is 10 be 4 x Lock Mount Bracket Holes: - -

[1.59mm] Deep (Both Ends). 9/64" [3.6mm] Dia. x 1/2” [12.70mm] - 23-128 ВАА]

| Deep For Wood Screws 5 [ 92mm]

dE _ — | .750

Cut Out This Area For + 1 [19.05mm]

.900 |} tock Mounting Clearance. —________ _ _ _5€Mget _— LL |

[22.86mm] 450 Note: Depth For Mounting Is To Be = 1.500

| [11.43mm] 1-1/8" P28 58mm] Deep Minimum. a [38.10mm]

(1 _ _ ©

| NY N |

RAN KR

= 9.600 [243.84mm] IA сне! С -

- 10.250 [260.35mm] - (8 Places) *

- 10.850 [275.59mm] -

SOLID WOOD TYPE FRAME

Flush Mount Brackets Not Used

SN Flan Mount Brackel Ho - 6.150 [156.21mm] -

x Flush Mount Bracket Holes: _ _

13/64” [5.2mm] Dia., Countersink 82° To 3/8" [9.5mm] 5.775 [146.69mm]

(Major) Dia. For Flat Head Machine Screws = 5.425 [137.80mm] -

( NN {

E) — — ©) 750

= [19.05mm]

900 > E Magnet

[22.86mm] DE. > —— AM zz DO

| 450 = 1.500

[11.43mm] 7 _ © _ O [38.10mm]

| Ny NS |

a TP

- 10.850 [275.59mm] = DL Chisel Corners

À

11.550 [293.37mm]

12.300 [312.42mm]

HOLLOW METAL AND ALUMINUM / STEEL TYPE FRAMES

Flush Mount Brackets Used

Square (4 Places)

P/N 500-20100—G

DO NOT PHOTOCOPY TEMPLATE (dimensions will change)

(Sheet 1 of 3)

—JECURITRON

ASSA ABLOY

Template For SAM Series — Strike Assembly

= == == = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = — = — — — — — - Strike Top Assembly View — For:

77 ST

O 5 a ©

| a Do |

| \ - 7 ___0|_ 27 |

A ос

_ I _ E E Strike

| > a --- |

| \ ‘ A >, >, \ ( / ( р р | © |

| NE No e |

LL J

Reference Only!

Cut Out This Area

5 x Base Mount Bracket Holes:

For

Strike Idle Plate Mounting.

Note: Depth For Mounting Is To

Deep For Wood Screws 2 y Clearance Holes:

5/16" ]

Be 1” [25.40mm] Deep Minimum. —T X 16,

9/64" [3.6mm] Dia x 1/2" [12.70mm]

[7. 9mm| Dia.

E Strike

|

[6.35mm] Deep

- 2.750 [69.85mm]

- 2.500 [63.50mm]

— 1.750 [44.45mm]—

4.500 [114.30mm]

Ÿ

| |

| |

| |

| |

| |

| |

| |

| |

5 IE

| |

— — — 1y .725

| © [18.42mm] |

| ‚800 | e + _ A € Strike In | | 1.450 |

| [20.32 тт] A | Nu [36.83mm] |

| | Y m |

© - - ®-

| 400 N A |

| . | |

| [10.16mm] - 3.500 [88.90mm] - !

| _ 5.000 [127.00 _ Chisel Corners Square |

| - . [127.00mm] - (4 Places) |

' - 5.500 [139.70mm] -

- 9.000 [228.60mm] -

HARD CORE WOOD TYPE DOOR

| End Mounting Brackets Not Used |

р]

о ато оо и 428 [137 80mm -

| | 4 x End Bracket Mount Holes: - | |

| 13.18mm] Deep (Both Ends). 9/64” [3.6mm] Dia. - 5.125 [130.18mm] | | |

| | X 1/2” [1 2, 70mm] Deep == 4.800 [1 21 92mm] To | |

| Zz ÓN | | À |

| AE — — HS — .725 |

| Cut Out This Area For [18.42mm] |

| . ‘ D |

| 900 | Strike Mounting Clearance. _ _ _ = GC Strike _ _ _ _ | 1.450 |

| [22.86mm] 450 Note: Depth For Mounting Is To Be > L36.83mm |

| [11.43mm] A 1-13/32” [35.72mm] Deep Minimum. о! x |

| | BRS a ) i |

| \_ |

| с” € |

| |

| - 9.600 [243.84mm] - HR hice Corners Square |

| - 10.250 [260.35mm] - (8 Places) |

| - 10.850 [275.59mm] - |

| SOFT CORE TYPE WOOD DOOR

| End Mounting Brackets Used |

P/N 500—20100—G DO NOT PHOTOCOPY TEMPLATE (dimensions will change) (Sheet 2 of 3) JECURITRON

ASSA ABLOY

Template For SAM Series — Strike Assembly

NA — — NT

oo S a o

| au NU |

| a - --®|---- VL} |

| TEN À Strike |

wot" - Le HE 00e (@ - — - —-

| 7 IX e TIN |

| O CUE © |

| LA NI _ |

LN J |

6

13/64” [5.2mm] Dia., Countersink 82° To 3/8" [9.5mm]

Xx Flush Mount Bracket Holes:

6.150 [156.21mm]

OPEN CHANNEL ALUMINUM AND TOP RAIL CHANNEL (HERCULITE) TYPE DOOR

Flush Mount Brackets Not Used

|

|

(Major) Dia. Through Frame Material Thickness - 5.775 [146.69mm] - |

For Flat Head Machine Screws - 5.425 [137.80mm] - |

Y a NN 7 | Ä

a @ |

+ — — D ‚750

u С |

300 ND © N [19.05mm] |

x |

20 LO) -1— -— o ae 75S

| ‚450 >) 1.500 |

[11.43mm] Za _ _ (© [38.10mm]

| NZ N |.

\_ A |

> |

— 10.850 [275.52mm] — > > File Corners |

= 11.550 [293.37mm] - Square |

- 12.300 [312.42mm] — (4 Places) |

FLUSH TOP HOLLOW METAL AND ALUMINUM TYPE DOOR |

Flush Mount Brackets Used |

AEB Mentes NR ana aa

9/64" [3.3mm] Dia. Holes Through Frame Material. _ _

For: Sheet Metal Screw Mounting Or Tapping 5.125 [130.18mm] |

8—32 UNC [M4 x .07] Machine Screw Mounting - 4.800 [121.92mm] |

> 7 < |

\ Г |

т Note: If Mounting In Top Rail Channels; _ D— |

Do Not Drill and Tap Through Channel | ; .725 |

Cut Out Area For: 1/8” [3.18mm] [18.42mm] |

or Shoe Material Into Glass Door. D y, . »

‚900 | =| sti To 1-3/8" [34.93mm] Deep Channels 1-1/2

[22.86mm] - B= Strike 0 oC TT 26 а | [38.10mm]

450 Cut Out Area Not Needed For: 1—1/2” [ 56. mm] Minimum

| [11.43mm] © [38.10mm] To 2” [50.80mm] Deep Channels |

® - - p—

) | N |

|

= ( |

- 9.600 [243.84mm] SN File Corners |

- - Square

10.250 [260.35mm] (4 Places)

|

|

|

P/N 500—20100—G

DO NOT PHOTOCOPY TEMPLATE (dimensions will change)

(Sheet 3 of 3)

—JECURITRON

ASSA ABLOY

">

/

Herunterladen

Nur eine freundliche Erinnerung. Sie können das Dokument direkt hier ansehen. Aber was am wichtigsten ist, unsere KI hat es bereits gelesen. Sie kann komplexe Dinge einfach erklären, Ihre Fragen in jeder Sprache beantworten und Ihnen helfen, auch in den längsten oder kompliziertesten Dokumenten schnell zu navigieren.